Building Envelope Components

The building envelope includes the surfaces and components that provide the physical separation between the conditioned, inside space and the unconditioned, outside environment. It isolates the occupants and other sensitive and valuable items inside the building from the elements.

The numerous functions the envelope serves can be broken down into three categories:

1. Control of the flow of matter and energy, which is done with both active and passive means.

2. Support of structural loads.

3. Finish of the outside and some inside surfaces

Resisting rain and controlling its flow off and away from the building is a fundamental function of the building envelope. That is accomplished with “perfect barriers”, such as roofs, rainscreens and wall systems that resist and/or redirect rainwater, walls that store rain water that isn’t shed or redirected, which is how massive stone structures function, and below grade waterproofing.

The building envelope also serves to control air flow. Windows and skylights that can be opened and closed are perhaps the most obvious examples of envelope components that can be used to control air flow in and out of the building. With the air comes water vapor, another component of the atmosphere that the envelope design must accommodate.

Finally, the envelope needs to serve as the primary means of controlling the inside temperature. Envelope components that serve that function range from concrete panels and reflective surfaces to thermal breaks and insulation.

Air and Vapor Barriers

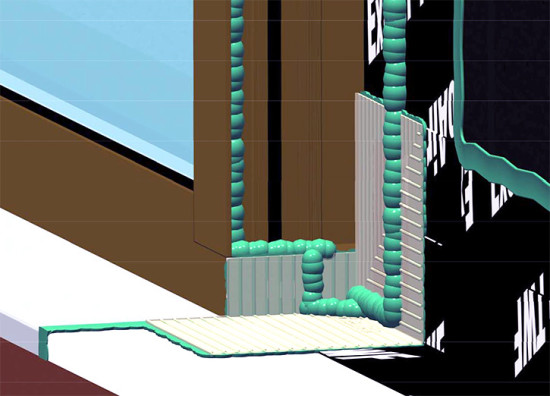

Air barrier systems include multiple materials, such as building wraps and sealants, and components, including windows, that seal the building enclosure, which includes all six sides of the building. Air barriers are also sometimes used to separate building sections from each other. Air barriers serve to wrap the building shell and protect the building elements within it from the effects of air leakage. The International Energy Conservation Code (IECC) includes requirements for air exchange between the inside and outside of buildings that can only be achieved with effective air barriers. Currently (2016) the ABAA lists twelve states and the District of Columbia as government authorities with air barrier requirements in their building codes.

Insulated wall assembly with air and water barrier intended to meet International Energy Conservation Code. Model by Dow Building Solutions

Scroll to zoom in on the 3D model and drag to orbit about it. Drag cursor + SHIFT to pan

General Information on Air and Vapor Barriers

A comparison of fluid applied and self adhered air barriers

This article from the July, 2014 issue of Design + Durability Magazine compares “fluid-applied” air barriers, which are brushed, rolled or sprayed on sheathing or other substrates with those that adhere to the underlying surface with an integral, pressure sensitive adhesive.

Evaluation of Air Barrier Types

Oak Ridge National Laboratory tested eight types of air barriers to see where air passes through them so that they can be made to meet the requirements of IECC 2012. A useful aspect of this presentation is the clear imagery of the mock-up wherein the components are identified and clearly shown.

System Assembly Performance Adhesion & Compatibility Component Movement Capability

BEST 2010- Building Enclosure Science & Technology Conference presentation by Tremco on their Exoair Air / Vapor barrier components installed at two hospitals in the Mid West. Much of the presentation is on the testing that was done to prove that the installed systems would function as intended.

“The Technology of Air Barriers: A Durability + Design Collection”

This eBook consists of articles from Durability + Design Magazine and the Journal of Architectural Coatings (JAC) on technological advancements in architectural air barriers.

Manufacturers and Suppliers of Air and Vapor Barriers

Carlisle Coatings and Waterproofing

Fluid applied air and vapor barriers, flashing, self adhering air and vapor barriers

CavityComplete Wall Systems

Complete steel stud / masonry cavity wall with Owens Corning, Tremco and other manufacturer’s products integrated into a single, warrantied system.

DuPont Tyvek Fluid Applied WB

Mortar Net Solutions

“Moisture Management for Masonry”

Sto Corporation

Manufacturer of air and moisture barriers, EIFS components and systems, stucco systems, cement board stucco systems, back-up wall systems, specialty wall systems, finishes and coatings

Tremco, Inc. Proglaze© ETA Air Barrier Transition Assemblies

Building Envelope Components Suppliers

Hohman & Barnard

Hohmann & Barnard, Inc. is a supplier of many and diverse masonry and concrete products and accessories including wall ties and anchors, seismic anchors and tees, lintels, glass block anchors and reinforcements, concrete inserts, expansion and control joints, air and vapor barriers, vents, weeps, flashing, reglets, and repair and restoration hardware.

Masonry Technology Inc., Cresco, IA

In addition to supplying many waterproofing components MTI is a resource for designers and specifiers by providing CAD models, specifications, data sheets and other forms of information. Their web site is one of the best of any supplier’s.

Exterior Insulation Finish Systems – EIFS

EIFS, exterior insulation and finishing system, is a class of building cladding systems. It is a non-load bearing composite that provides insulation, water-resistance and a finished surface that can simulate just about anything. It was originally developed in Europe after World War II where it is know as External Wall Insulation System (EWIS) and External Thermal Insulation Cladding System (ETICS).

As in Europe, EIFS was first used in the 1960s in North America on masonry buildings, but since the 1990s the majority of EIFS installations have been on wood framed structures. EIFS has to be properly installed and as the popularity of the material exploded water infiltration problems grew resulting in a huge number of legal cases. Since then EIFS has continued to be used because, despite the need for quality control, it is a very good way to clad buildings.

The model below shows and EIFS (External Insulation Finish System) assembly with a mechanical fastener securing insulation onto sheathing sealed with WRB (weather resistant membrane) which is covered with a mesh that holds a base coat onto which is applied the finish coat.

Scroll to zoom in on the 3D model and drag to orbit about it. Drag cursor + SHIFT to pan

Design + Durability Magazine Article on EIFS Building Cladding

“A Versatile Cladding For Buildings” by David Johnson and Scott Robinson of the EIFS Industry Members Association (EIMA) – Durability + Design Magazine – January 2015

Dryvit Systems, Inc.

Dryvit is to EIFS as Kleenex is to facial tissue. They were among the first to manufacture EIFS materials in North America in the 1960s and continue to lead the industry, which wouldn’t be the case if they didn’t provide complete and accurate data and instructions. This site includes pages on all their products including repair instructions and recommended materials to use while repairing, restoring and maintaining EIFS components.

Dow Corning EIFS Restoration Guide

“The recommendations in this guide are not intended to replace those of a qualified industry consultant or engineer who can investigate and evaluate the existing condition of a particular EIFS building.”

DuPont Tyvek Fluid Applied Weather Barrier

Sto Corporation

Manufacturer of air and moisture barriers, EIFS components and systems, stucco systems, cement board stucco systems, back-up wall systems, specialty wall systems, finishes and coatings

Flashing

Kick Out (Kickout, Kick-Out) Flashing FAQ for Home Inspectors, Installers and Homeowners

This detailed article on Paragon Property Services web site describes a project at a home where walls were damaged due to the lack of water diversion off of a roof. Drawings and photographs clearly depict what was wrong and how the defects were corrected.

Rainscreen

Masonry Technology Inc., Cresco, IA

In addition to supplying many waterproofing components MTI is a resource for designers and specifiers by providing CAD models, specifications, data sheets and other forms of information. Their web site is one of the best of any supplier’s.

Walls

Curtain Walls in the National Institute of Building Sciences Whole Building Design Guide

National Concrete Masonry Association “Design For Dry Single-Wythe Concrete Masonry Walls”

Durable Waterproofing for Concrete Masonry Walls: Redundancy Required by Robert M. Chamra, EIT & Beth Anne Feero, EIT

Masonry Details by the International Masonry Institute

The value of the work that the International Masonry Institute has done or commissioned to describe and disseminate useful information on masonry construction is hard to overstate. The 3D models that they provide on this page are one of many testaments to that fact.

Model of a Double Wythe Wall by the International Masonry Institute

Scroll to zoom in on the 3D model and drag to orbit about it. Drag cursor + SHIFT to pan

Retrofitting Building Envelopes

Preventing and Treating Distress in Brick Veneer Cavity Walls

Hoffman Architects Journal article for January, 2016 on brick walls explaining how they are built and maintained as well as what can go wrong with them and how they are repaired.

Replacing a building’s envelope may seem to be a drastic solution for increasing energy efficiency but it can be done in a number of ways. This June 2016 article in Durability+Designn magazine describes the three general approaches in use today.

Storefront Rehabilitation and Design

This Hoffman Architects Journal Article for January 2018 describes storefronts and differentiates them from curtain walls and window walls. It offers details and descriptions on storefront design and construction, how the doors within them function, how they transfer or withstand heat and cold, wind and structural loads and the factors that effect them over time. It also offers guidance on how to evaluate them and how to treat problems associated with them. Many of the points in this part of the article are applicable to other components of the envelope, such as curtain and window walls.

Presentation Brief #2 Repointing Mortar Joints in Historic Masonry Buildings

National Park Service US National Park Service

Technical Note 7 Maintenance of Brick Masonry

on Design and Detailing for Water Penetration Resistance

Technical Notes on Brick Construction by the Brick Industry Association

“The Perfect Wall“

Thermal and Moisture Control in Exterior Metal Walls

Part of an AIA/Architectural Record Magazine continuing education series.

Weeps

Weep Holes, Drainage & Moisture Ventilation in Brick Walls

Weep Primer by John Koester, the CEO of MTI

Well written and exceptionally well illustrated article on weeps from the April, 2013 edition of The Construction Specifier. It’s one of several at MTI’s site on moisture management.

Mortar Net Solutions WeepVent™

Compressible, 90% open weave polyester mesh with “prickly adhesion” to hold the weep in place without adhesive.

Product Data Sheet for Cell Vent Insertable Weep at MASONPRO.com

QV – Quadro-Vent on Hohman & Barnard Site

Bug Out Weeps

CavClear Poly Mesh, Notched Design, Colored Weep Vents

Insect Shield at 100 Stevens Drive, Philadelphia

Masonry Technology, Inc. weep products

Windows and Glazing

Dow 2007 Fenestration Technical Manual

Thermal Window Failure: How it Happens by Dr. John Straube

Through animations and Straube’s clear prose the mechanisms and conditions that lead to the failure of the seals in thermal windows are explained.

Water Penetration Resistance of Windows

Study of Manufacturing, Building Design, Installation and Maintenance Factors

Weighing the Costs and Benefits of Window Replacement

This facilitiesnet.com article dresses replacement costs and other considerations regarding windows in commercial buildings. Useful, general information on frames, glazing and finishes is provided.