The Construction Specification Institute currently includes “Sealants” in Section 07000, “Thermal and Moisture Protection”. The term “Calking” was in previous iterations, but since 2004, it does not appear in any CSI section.

For architects and others with the need for specificity in identifying construction and building restoration materials, “Caulk” and “Sealant” are NOT the same. “Caulking” and “calking” are the terms used to refer to the gunnable products used as a filler between building components and materials in interior spaces where the environment is controlled and joints don’t expand or contract. Sealants are installed in dynamic joints, the joints between components on the exterior or non-environmentally controlled spaces of buildings and infrastructure. The performance requirements, and therefor the characteristics, handling, chemistry, manufacturing methods and costs of the two are vastly different.

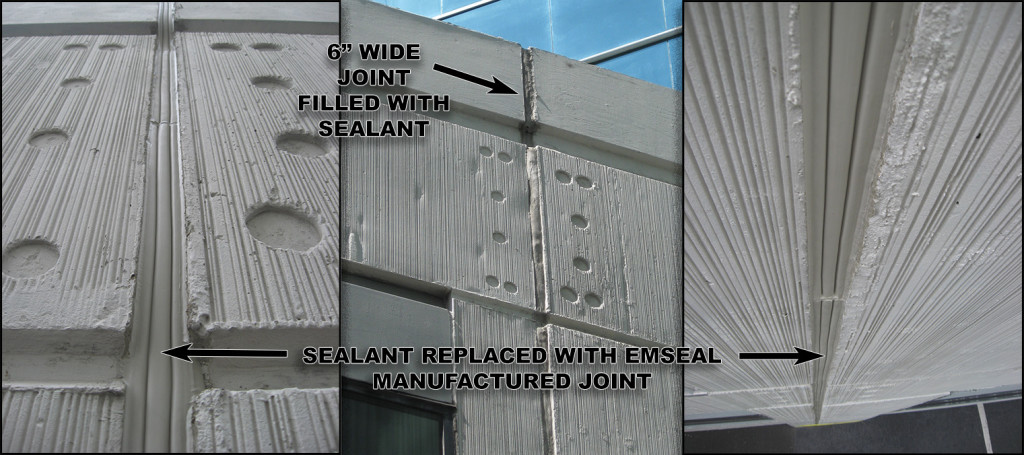

Manufactured Joints and Extrusions

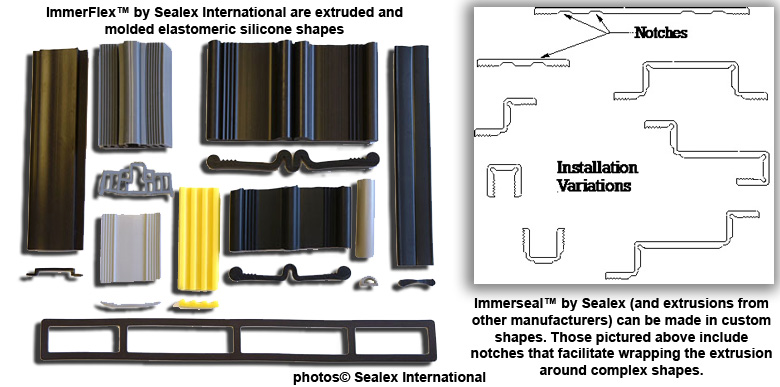

Usually, gunnable sealant is used to seal the joints in buildings but when joint width exceeds the standards, factory made assemblies can be a reliable alternative. Some waterproofing problems involving surfaces and edges that form irregular or out-of-plane spaces can be corrected with custom shapes. Leaking skylights or windows, leaks in a metal roof, leaks or punctures in RV’s or cargo trailers, and various wet seals may involve interfaces that may be best restored with custom shapes.

Silicone Extrusions

Some waterproofing problems involving substrate surfaces with insufficient sealant contact area or edges that form irregular or out-of-plane spaces shouldn’t be corrected with conventional wet seals. Leaking skylights or windows, leaks in a metal roof, leaks in RV’s or cargo trailers may involve such interfaces.

Sealant Restoration and Installation

Manufacturer’s Services

DOW Corning Construction Project Services

Dow’s support includes specification review, color matching service, mock-up consultation, application training and adhesion testing for warranties.

Methods and Guidelines

The Art of Tooling

Properly installed joints are formed with tools made for the task in the hands of skilled tradesmen. Calling it an art isn’t accurate but it is definitely a trade, and not one easily mastered.

Dow Corning Guide for Restoring Joints in EIFS

Dow sealants are used in EIFS components and systems. The preface of this comprehensive guide states: “This document is intended to provide installation and field testing instructions for Dow Corning® brand sealants, coatings and primers for EIFS applications in order to provide building owners the longest lasting weatherproofing system available. While this guide provides product-specific EIFS restoration procedures, the recommendations in this guide are not intended to replace those of a qualified industry consultant or engineer who can investigate and evaluate the existing condition of a particular EIFS building.”

Canadian Precast/Prestressed Concrete Institute Sealant and Joint Guide

Topic headings in this comprehensive guide are: Building Science Principles Behind Joint Design, Sealant & Joint Design, Cold Weather Sealant Applications, Joint Backing/Bond Breaking, Sealant Staining & Dirt Pick-Up, Joint Preparation, Fire Protective Treatment, Air Barriers, Sealant Installation, and Sample Specification.

Challenges in Sealant Applications

Excessive expansion joint movement during the curing cycle of freshly installed architectural sealants due to ambient temperature fluctuations can plague a project. This article describes the causes, effects and remedies for this problem.

Joint Sealants in the National Institute of Building Sciences Whole Building Design Guide

The “Whole Building Design Guide” is an exhaustive publication funded by the Federal Government of the United States by the National Institute of Building Science. The topics in this article on joint sealants are: Sealant Selection, Key Features of Sealant Chemistry, Joint Types, Common Sealant Application Problems, Joint Design and Sealant Installation. Relevant codes, standards and guidelines are listed and links to specifications for projects for the US Department of Defense and Department of Veterans Affairs are also provided.

Master Wall Technical Bulletin on Sealant Joint Design

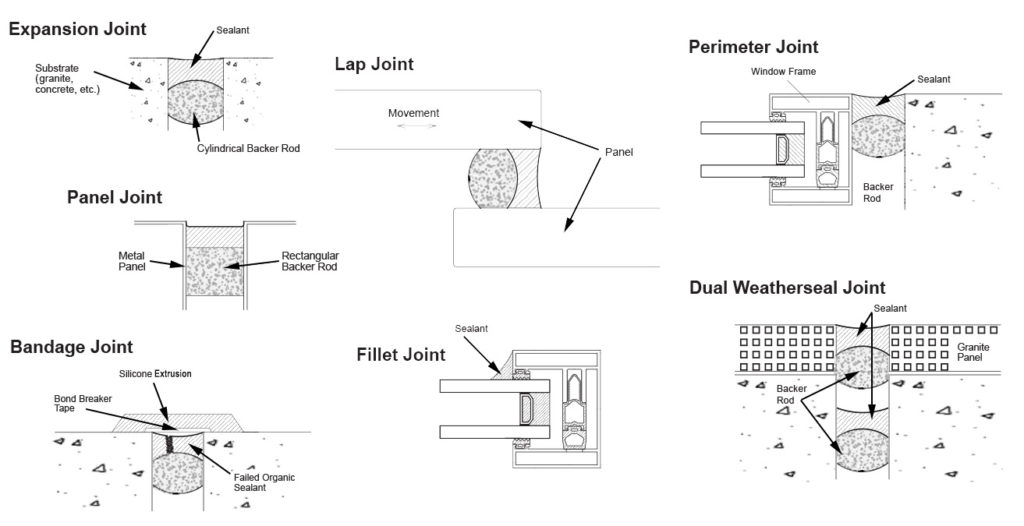

Simple graphics depicting “butt”, “fillet” and “band-aid” type joints are provided as well as fundamental methods for determining the correct joint width.

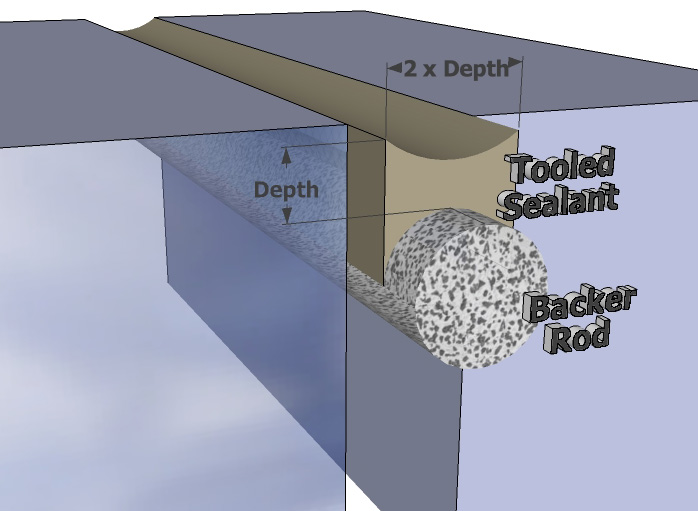

Backer rod forms the bottom of the “hour glass” shape of the joint. The tradesman who installs the joint uses the proper tool and technique to form the top and to force the sealant into the space and to bring it into full contact with the substrate.

How to tool a sealant joint is demonstrated. Although the joints that are sealed are in a horizontal surface the tools and technique shown are the same for vertical joints.

Pecora Corporation “Resources”

Pecora is one of the top sealant and waterproofing manufacturers. The information they offer in their Technical Bulletins include:

Application Information:

TB 31 Painting Over Sealants

TB 106 Backer Rod Use

TB 108 Sealant Application Guide

TB 169 Applying Sealant in Expansion Joints Over 1″ Wide

Adhesion Information:

TB 54 Evaluating Field Adhesion of Installed Elastomeric Sealants

TB 55 Field Adhesion Test Procedures

TB 55A Field Adhesion Test Log

TB 74 Two Cloth Cleaning Procedure

TB 76 Adhesion of Sealant to WeatherClad

TB 111 Using Pecora Silicone on Pre-Cast Concrete

Primer Guidelines:

TB 25 Primer Coverage Chart

TB 109 Pecora Silicone Construction Sealants Adhesion and Primer Guidelines

TB 110 Pecora Urethane Construction Sealants Adhesion and Primer Guidelines

Weather Considerations:

TB 65 Caulking At Low Temperatures

TB 190 Sealant Application Temperature Guidelines

TB 193 Low Temperature Application of Pecora XL-Perm Ultra VP Air, Vapor, and Water Resistive Barrier Membrane

Exterior Insulated Finish Systems (EIFS):

TB 179 Sealant Adhesion to STO EIFS Base Coats

Joint Inspection, Preparation:

TB 74 Two Cloth Cleaning Procedure

TB 103 Sealant Joint Inspection

TB 174 Sealant Joint Inspection Checklist

TB 179 Sealant Adhesion to STO EIFS Base Coats

Manuals and Handbooks

Dow Corning 2016 Technical Manual

Dow Corning’s manual on proper application of their silicone sealants

Masterwall

Master Wall technical bulletin on sealant joint design

Simple graphics depicting “butt”, “fillet” and “band-aid” type joints are provided as well as fundamental methods for determining the correct joint width.

Tremco

Tremco Sealant Restoration Guide

This excellent publication covers most of the important topics. The sections are:

1. Documenting Performance

2. Your Tremco Field Representative

3. Identifying the reasons for joint sealant restoration

4. Joint sealant restoration options

5. Selecting the appropriate products

6. Determining the joint restoration approach

7. Product installation guidelines

8. Appendix

a. types of substrates

b. Calculating joint movement

c. Sealant joint design

d. Sealant joint profiles

e. Joint sealant guide specification

USDA Residential Caulking Guide

Although written for homeowners and others concerned with residential buildings most of the subjects are just as relevant to commercial buildings.

Wet Seals

Wet Sealing by Karl A Schaak, RCI

Definition: an elastomeric, gun-grade joint sealant at the interface of a glass unit and the adjoining frame and/or gasket of an existing window unit.

Silicone Extrusions

Some waterproofing problems involving substrate surfaces with insufficient sealant contact area or edges that form irregular or out-of-plane spaces shouldn’t be corrected with conventional wet seals. Leaking skylights or windows, leaks in a metal roof, leaks in RV’s or cargo trailers may involve such interfaces.

Sealant Restoration Materials

Sealant Page on the Materials and Finishes Portion of JBSBS.com

Structural Glazing Joints

Structural Silicone Glazing: Changing the Face of Architectural Design

Dow Corning paper, illustrated with 3D drawings, on modern structural glazing.

Tuckpointing

Repointing Mortar Joints in Historic Masonry Buildings video series

Lime Mortar Repointing

Reasons to replace mortar joints in old masonry, lime versus cementitious mortar and other point are discussed in this first video of the series by Preservation Works of Easton, Pennsylvania, USA. This video references Preservation Brief 2 by the U.S. Park Service.

Techniques for Safely Removing Mortar

Methods and tools used to remove mortar from joints are given in this second video of the series by Preservation Works of Easton, Pennsylvania, USA. This video references Preservation Brief 2 by the U.S. Park Service.

How Sealant (caulk) Damages Mortar Joints

Why sealant should not be installed in mortar joints is explained in this third video of the series by Preservation Works of Easton, Pennsylvania, USA.