Sealant

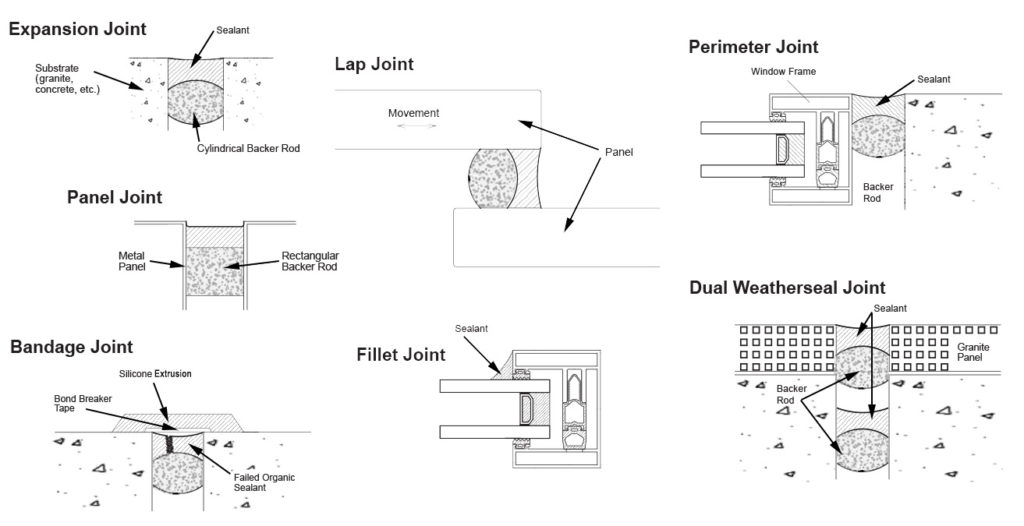

The Construction Specification Institute currently includes “Sealants” in Section 07000, “Thermal and Moisture Protection”. The term “Calking” was in previous iterations, but since 2004, it does not appear in any CSI section. For architects and others with the need for specificity in identifying construction and building restoration materials, “Caulk” and “Sealant” are NOT the same. “Caulking” and “calking” are the terms used to refer to the gunnable products used as a filler between building components and materials in interior spaces where the environment is controlled and joints don’t expand or contract. Sealants are installed in dynamic joints, the joints between components on the exterior or non-environmentally controlled spaces of buildings and infrastructure. The performance requirements, and therefor the characteristics, handling, chemistry, manufacturing methods and costs of the two are vastly different.

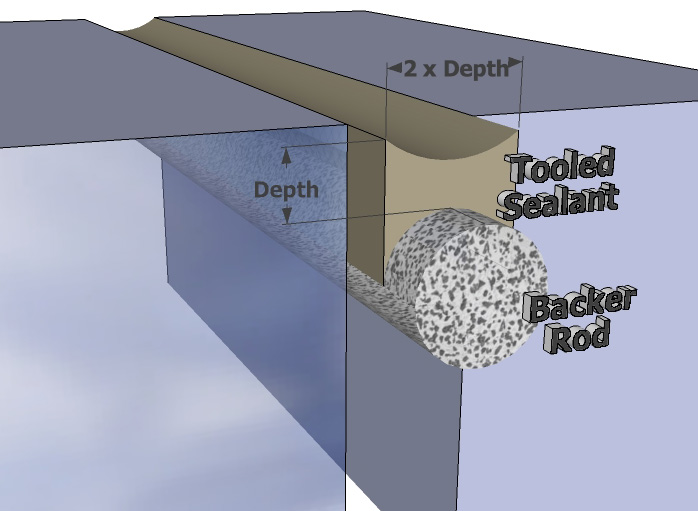

Backer Rod

Use of Sealant Joint Backing Materials – Pecora Corporation Technical Bulletin # 106

Backer rod and backer tape are used to control the joint depth and to prevent the back of a sealant joint from contacting surfaces to which it could adhere. When the back of a sealant joint adheres to the building a condition called “three point (or three sided) adhesion” occurs. When both sides of the sealant joint and the back are bound to the building potentially damaging stresses are introduced in the sealant as it elongates and compresses to accommodate joint movement. Backer rod or tape is to be used when joint movement is expected to exceed fifteen percent.

This mildly informative bulletin includes hints on using backer rod and backer tape, including guidance to install backer rod before primer application to avoid contamination of the primer or the joint wall from dust or debris from adjacent spaces in the wall.

BASF Backer Rod

MasterSeal® 920 is a closed-cell, polyethylene foam joint-filler and backing for elastomeric sealants. Its resilience accommodates dynamic joints. MasterSeal® 921 is a reticulated closed-cell polyethylene foam joint-filler and backing for sealants. It compresses easily to accommodate joints of varying widths.

Butyl (Polyisobutylene, also known as “PIB” or polyisobutene)

Butyl tape is used in construction and marine applications. Bed-It Tape, is a proprietary formulation and a butyl hybrid developed by Compass Marine, Inc. for “bedding” deck hardware. Trex Protect Joist, Beam and Rim Tape covers the top, horizontal surfaces of wood deck joists, beams and ledgers and the outside vertical surfaces of deck rim boards. Both of these products illustrate how butyl tape is generally used to prevent water entry into penetrations created by screws and other fasteners.

H.B. Fuller Article on Butyl Window Sealant

Wikipedia Article on Butyl Rubber

General Sealant Information

Adhesives.org and Sealants.org Site Map

Adhesives & Sealants Industry Magazine

The Art of Tooling

Properly installed joints are formed with tools made for the task in the hands of skilled tradesmen. Calling it an art isn’t accurate but it is definitely a trade, and not one easily mastered.

Challenges in Sealant Applications

Excessive expansion joint movement during the curing cycle of freshly installed architectural sealants due to ambient temperature fluctuations can plague a project. This article describes the causes, effects and remedies for this problem.

Comments From the Field

Readers comments and questions on previous articles on the use of sealants on Lexan and Plexiglass and things to consider when painting sealant joints.

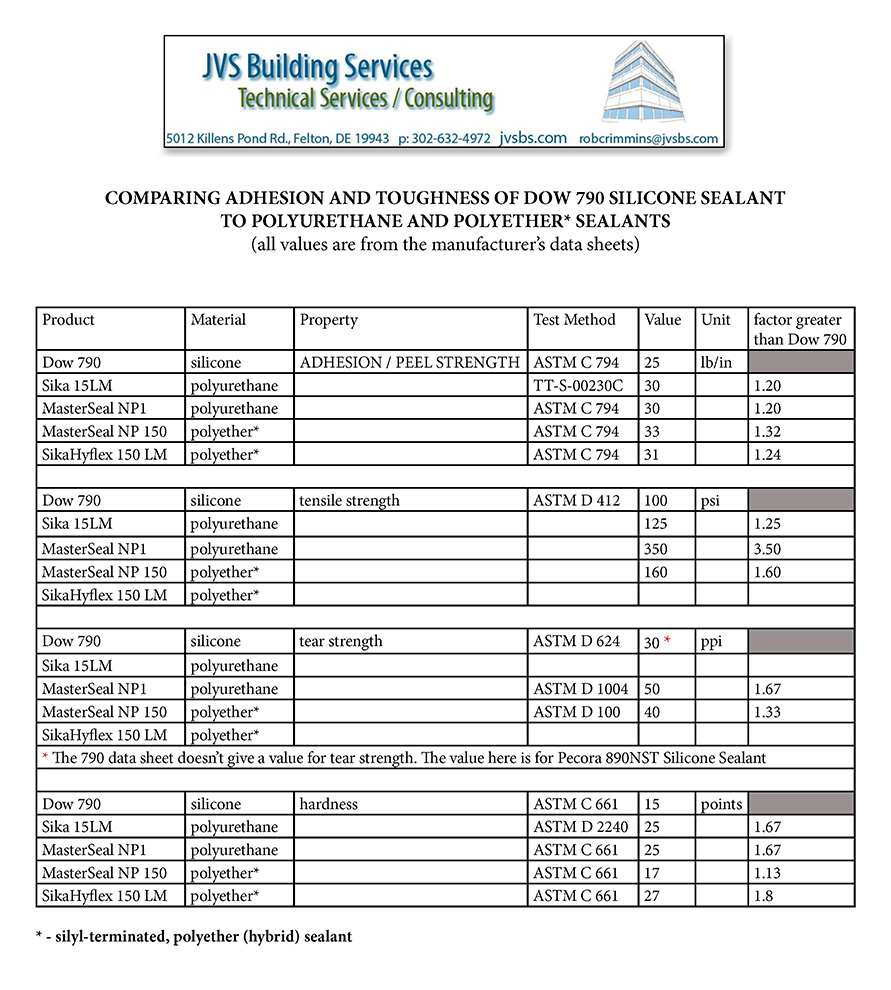

Comparing Toughness and Adhesion of Silicone, Polyurethane and Silyl-terminated (hybrid) Sealant

Because of the chemistry, silicone sealants, which are based on inorganic bonds (Si-O) are inherently more UV resistant than polyurethanes, which rely on organic chemical (C-O) bonds. Although silicone sealants are more expensive they are typically the better choice for joints in vertical surfaces because they last much longer. Polyurethane is much tougher and that is why it is used in joints in traffic bearing surfaces. Hybrid sealants are essentially combinations of polyurethanes or polyethers and silicones. They are referred to in the adhesive and sealant industries as Silyl Terminated Polyether (STPE), modified polyurethane, MS (Modified Silicone) Polymer, SMP (Silyl Modified Polymer and Silane Modified Polymer), silane end-capped urethane and STPU (silyl-terminated polyurethane). Properly formulated, hybrid sealants are strong and tough like polyurethanes but with better weathering resistance. The chart below compares the adhesion / peel strength, tensile strength, tear strength and hardness of Dow 790 Silicone with two high quality polyurethanes, Sika 15LM and BASF MasterSeal NP1, and two good hybrid sealants, BASF MasterSeal NP 150 and Sika Corporation SikaHyflex 150 LM.

Durability of Elastomeric Sealants

Although nearly all architectural specifications for sealant demand compliance with ASTM C920, that guide calls for a sealant to endure only 250 hours in an accelerated weathering machine. Little data is available to demonstrate which sealants sold for sealing exterior joints in building envelopes can withstand long periods of exposure. This article in The Construction Specifier magazine discusses the factors that can be considered to determine how long a sealant may last and some of the testing that is done to find the answer to the question.

Joint Sealants in the American of Institute of Architects Journal

Joint Sealants in the National Institute of Building Science Whole Building Design Guide

The National Institute of Building Sciences was authorized by the U.S. Congress in the Housing and Community Development Act of 1974, Public Law 93-383. In establishing the Institute, Congress recognized the need for an organization that could serve as an interface between government and the private sector. The Institute’s public interest mission is to serve the Nation by supporting advances in building science and technology to improve the built environment. Through the Institute, Congress established a public/private partnership to enable findings on technical, building-related matters to be used effectively to improve government, commerce and industry.

The tradesman who installs the joint uses the proper tool and technique to form the top of the joint, to force the sealant into the space and to bring it into full contact with the substrate.

Pecora Corporation “Resources”

Pecora is one of the top sealant and waterproofing manufacturers. The information they offer in their Technical Bulletins include:

Application Information:

TB 31 Painting Over Sealants

TB 106 Backer Rod Use

TB 108 Sealant Application Guide

TB 169 Applying Sealant in Expansion Joints Over 1″ Wide

Adhesion Information:

TB 54 Evaluating Field Adhesion of Installed Elastomeric Sealants

TB 55 Field Adhesion Test Procedures

TB 55A Field Adhesion Test Log

TB 74 Two Cloth Cleaning Procedure

TB 76 Adhesion of Sealant to WeatherClad

TB 111 Using Pecora Silicone on Pre-Cast Concrete

Primer Guidelines:

TB 25 Primer Coverage Chart

TB 109 Pecora Silicone Construction Sealants Adhesion and Primer Guidelines

TB 110 Pecora Urethane Construction Sealants Adhesion and Primer Guidelines

Weather Considerations:

TB 65 Caulking At Low Temperatures

TB 190 Sealant Application Temperature Guidelines

TB 193 Low Temperature Application of Pecora XL-Perm Ultra VP Air, Vapor, and Water Resistive Barrier Membrane

Exterior Insulated Finish Systems (EIFS):

TB 179 Sealant Adhesion to STO EIFS Base Coats

Joint Inspection, Preparation:

TB 74 Two Cloth Cleaning Procedure

TB 103 Sealant Joint Inspection

TB 174 Sealant Joint Inspection Checklist

TB 179 Sealant Adhesion to STO EIFS Base Coats

Pecora’s “Master Caulksmith”

The Master Caulksmith is Roy Cannon, Pecora Corporation’s Director of Technical Services. These articles and podcasts address several issues that repeatedly come up during the sealant selection and application process.

Polysulfide and Polyurethanes as Marine Sealants

This March / April 2000 article by Scott Thurston in Good Old Boat Magazine describes these two major categories of marine sealants and compares them. The marine context is of interest: ” ‘Stockholm tar’ is still fondly remembered mostly for its pleasant aroma. This was used to waterproof hulls and rigging back in the days of wooden ships and iron men. These old products worked reasonably well and (within the technology of the day) demanded no more maintenance than did the rest of the vessel. But because they were organic, they would eventually dry out or decay. The basic families of these mastics are still available, even today, under the generic title of “bedding compounds,” though their chemistry has become a little more refined over the years.”

Power & Motoryacht Magazine article on sealant

Sealant Joint Rehabilitation by Hoffman Architects

Silicone or Urethane?

Why choose one over the other?

Tremco Sealant Restoration Guide

This excellent publication covers most of the important topics. The sections are:

1. Documenting Performance

2. Your Tremco Field Representative

3. Identifying the reasons for joint sealant restoration

4. Joint sealant restoration options

5. Selecting the appropriate products

6. Determining the joint restoration approach

7. Product installation guidelines

8. Appendix

a. types of substrates

b. Calculating joint movement

c. Sealant joint design

d. Sealant joint profiles

e. Joint sealant guide specification

Weathering Steel, The Proper Use of Sealants On

Weathering steel, often referred to by its U.S. Steel trademarked name, Cor-Ten steel requires special attention when it come to sealant adhesion. That is the subject of this February, 2017 Durability and Design article by Christopher Sass, an associate principal-level architect with Wiss, Janney, Elstner Associates Inc.

What comes first . . . the caulk or the paint?

Which comes first, the caulk or the paint? The answer to this question isn’t always the same. This article is about why that is true.

Why Sealants Fail

The reasons sealant joints fail are explained in this article by Karen Warseck, an architect with Building Diagnostics Associates of Hollywood, Florida, USA

Hybrid Sealants

These are products that are essentially combinations of polyurethanes or polyethers and silicones. They are referred to in the adhesive and sealant industries as Silyl Terminated Polyether (STPE), modified polyurethane, MS (Modified Silicone) Polymer, SMP (Silyl Modified Polymer and Silane Modified Polymer), silane end-capped urethane and STPU (silyl-terminated polyurethane). Properly formulated, hybrid sealants combine the strength and toughness of polyurethanes with the weathering resistance of silicones. Hybrid sealants do not hold as wide a market share in the United States and Europe as they do elsewhere, such as in Japan, where they are the most widely used type of sealant.

BASF Hybrid Sealants

Masterseal NP 100

Adheres to a variety of substrates and accommodates high movement while providing long term durability. This hybrid sealant is low modulus, non-sag, fast curing, and ready-to-use. It combines the best qualities of organic and silicone sealants to keep moving joints weather-tight.

MasterSeal NP 150 (formerly Sonolastic 150VLM) Product Technical Data Sheet

low-modulus, non-sag, elastomeric, hybrid sealant with superior adhesion and 100% extension in EIFS joints

MasterSeal NP 150 Tint Base

premium-grade, high-performance, multi-component tintable, non-sag, hybrid sealant.

MasterSeal SL 100

This product, introduced in September of 2016, is a one-component, self-leveling sealant. It’s different than most other sealants intended for joints in decks in that it can be applied on green and damp concrete substrates. It’s fast curing, skinning over in 5 to 35 minutes and it can be painted.

General Information on Hybrid Sealants

MS SMP or polyether polymer at Bostik.nl

Bostik is an adhesives manufacturer that was an early player in the development of hybrid sealants. This article is on the basic chemistry of the material.

MS Polymers in “Hybrid” Sealants Edward M. Petrie

This Adhesive and Sealant Council, Inc. article describes the basic chemistry and properties of “hybrid Sealants”, which are are essentially combinations of polyurethanes or polyethers and silicones. They are referred to in the adhesive and sealant industries as Silyl Terminated Polyether (STPE), modified polyurethane, MS (Modified Silicone) Polymer, SMP (Silyl Modified Polymer), silane end-capped urethane and STPU (silly-terminated polyurethane). Properly formulated, hybrid sealants combine the strength and toughness of polyurethanes with the weathering resistance of silicones.

Pecora Hybrid Sealants

This page is titled “Urethane Sealants for Construction” but three of the products on this page are designated “STPU (silyl-terminated polyurethane) Silicone/Urethane”, “STPU/Hybrid Sealant” and “Polyurethane STPU”. Dynatrol I-XL Tru-White is the STPU (silyl-terminated polyurethane) Silicone/Urethane. Pecora NR-201 is the STPU/Hybrid Sealant and Pecora Dynaflex™ SC is the Polyurethane STPU

Prosoco Corporation R-Guard AirDam Hybrid Sealant data sheet

OSI Quad® Max Sealant

QUAD MAX is marketed as siding & window sealant and for use sealing around interior/exterior windows, doors and siding and for its ability to adhere to a wide variety of materials without need for a primer such as fiber cement, cedar, brick, stone, coated aluminum, fiberglass, vinyl, PVC, stucco, EIFS, wood, glass, and flashing tapes and Kynar® coatings. Many of the products on this and other pages on JVSBS.com suitable for commercial use are only sold through commercial building supplies distributors. OSI Quad® Max and other OSI products are available at Home Depot.

Sika Corporation SikaHyflex-150LM Hybrid Sealant data sheet

premium-grade, high movement, fast curing, one component, non-sag, elastomeric, hybrid sealant. Meets ASTM C-920, Type S, Grade NS, Class 50, use NT, M, A, G, O

Soudal USA

Soudal’s Brochure includes information on their all purpose waterproofing and sealing material for general construction (SoudaSeal AP ), high bond strength, low modulus joint sealant (SoudaSeal 50LM), self leveling sealant for horizontal joints in sidewalks, patios and foundations (SoudaSeal SL), fast cure, high strength adhesive/sealant (SoudaSeal FC), crystal clear adhesive sealant (SoudaSeal CL) and a solvent free, high quality, single component HVAC ducting sealant for all types of metal ducts (SoudaSeal Metalbond).

Sealants and Flashing Materials For Masonry at MasonryMagazine.com

This article is about more than hybrid sealants, however a list of advantages that hybrids offer is included. Among those advantages are comparatively low viscosity at low temperatures, low VOCs, quick tack-free time and superior bonding characteristics.

Silco Eco-Flex 9500

one component, high modulus, mildew resistant multipurpose silyl-terminated polyether (hybrid) elastomeric sealant and adhesive

Tremco Sealants

This page on Tremco’s site has links to their polyurethane, silicone and hybrid polyurethane sealants. (Tremco refers to their hybrids as being “silane end-capped urethane” rather than “silly-terminated”, one of several terms used by others.)

Chem Link, Inc. – Schoolcraft, MI

Polyether (hybrid), polyurethane and silicone adhesives, sealants and liquid membranes for construction, marine applications and OEM.

Latex Sealant

Adhesives and Sealant Industry Magazine article on the use of vinyl acetate ethylene rather than acrylic monomers as binders in latex sealant.

Marine Sealant

WestMarine.com article and products description on their polyurethane, silicone, polysulfide, butyl, epoxy and polyether sealants.

Marine Caulking and Adhesives products from West Marine

Buildings and boats have much in common so many of the products made for marine applications can meet or exceed the needs of architectural assemblies. Architects may not typically specify them but resourceful contractors should be aware of them and include them in their tool boxes.

Polysulfide Sealant

From the WikipediA article: “Polysulfide polymers are insoluble in water, oils, and many other organic solvents. Because of their solvent resistance, these materials find use as sealants to fill the joints in pavement, automotive window glass, and aircraft structures.” Polysulfide sealants are used where there is prolonged immersion in liquids such as in swimming pools, fountains, cooling towers, chemical and fuel storage tanks, wastewater treatment and petrochemical plants. They are also used in boats and marine structures and to minimize crevice corrosion in joints in aircraft fuselages, areas of skin doublers, chord-to-skin joints for the wing and wheel structure, etc.

Evaluation of Polysulfide Sealant in Concrete Joints By the North Dakota Department of Transportation

Preformed neoprene compression joint sealers have been widely used in North Dakota their performance was found to be lacking. Polysulfide rubber joint sealant was evaluated to determine its suitability as a replacement. Both silicone and polysulfide joints had many leaks when tested with the I-Vac system and it was concluded that the polysulfide sealant did not perform any better than the silicone and using polysulfide rubber joint sealants is not recommended for joints in concrete road surfaces.

Pecora Corporation Synthacalk GC2+ Polysulfide Sealant

Sika Duoflex NS/SL Two-Component, Polysulphide Sealant

Duoflex NS is a USDA grade sealant

Sonnaborn Sonolastic Polysulfide Sealant

Thiokol 2282 Polysulfide Sealant

High polysulfide polymer content makes Thiokol 2282 resistant to many chemicals. It is flexible, does not shrink, ages well, resists thermal stress and the effects of outdoor exposure.

What Sealant Do You Need?

This BoatU.S. article discusses the differences between polysulfide, polyurethane and silicon sealant in the context of the marine environment.

Polyurethane Sealant

Alternate Uses

3M Marine Sealant

Although not used in building restorations projects because of its expense and also because of its properties, this material is one that architects and contractors should be aware of. It is very moisture resistant (it’s used below the waterline) and has very high adhesion. In fact, 3M 5200 Sealant is often stronger than the substrates to which its applied so care has to be taken in deciding when to use it rather than a less tenacious material if it’s possible that the joined items may eventually need to be disassembled.

BASF Polyurethane Sealant Products

BASF recently renamed their products assigning the prefix “Master” to their cement additives, concrete admixtures and fibers, concrete repair and protection products, grouts, performance flooring, underground construction products, waterproofing products and sealants. At the bottom of the page tied to this link: “BASF Products”, are drop down menus. The one labeled “Joint Sealants” presents links to the company’s polyurethane sealants, which are:

MasterSeal CR 125 (formerly: Sonomeric 1)

ready to use, self leveling, chemical, jet fuel and weather resistant sealant, with “exceptional integrity”, for use on airport runways and industrial floors

MasterSeal CR 195 (formerly: Sonolastic Ultra)

one-component, moisture-curing aliphatic, non-sag, polyurethane security sealant for institutional uses requiring elasticity, abrasion and puncture resistance, with superior color integrity.

MasterSeal NP1 (formerly: Sonolastic NP 1)

one-component, high performance, non-priming, gun-grade, elastomeric polyurethane sealant. It requires no mixing and typically requires no priming to bond to many materials, including concrete and masonry

MasterSeal NP 2 (formerly: Sonolastic NP 2)

multi-component, highly flexible, non-priming, high performance polyurethane sealant. It has been successfully tested for joint movement of ±50%. It can be tinted to multiple colors.

MasterSeal SL 1 (formerly: Sonolastic SL 1)

one-component elastomeric, self-leveling polyurethane sealant, for use in concrete floors, decks, for all climates

MasterSeal SL 2 (formerly: Sonolastic SL 2)

multi-component, self-leveling, elastomeric polyurethane sealant that is mixed and poured in place. When cured, it forms a tough, resilient joint seal that resists penetration and abrasion and remains flexible when exposed to weather and aging.

MasterSeal TX 1 (formerly: Sonolastic TX 1)

one-component, texturized, moisture-curing, gun-grade polyurethane sealant. It requires no mixing and typically requires no priming on common building materials. MasterSeal TX 1 has a textured appearance, which blends well with masonry substrates.

Pecora Polyurethane Products

Pechora produces a line of polyurethane joint sealants. Among them are Dynatred®, a non-sag traffic-grade product for horizontal joints on a slope of 5 degrees or more, self-leveling, 2-part sealants, fuel and blast resistant products, general purpose one-part sealants, security sealants and hybrids. Polyurethane sealants for use between materials of similar or dissimilar surface textures, porosities or expansion coefficients. These materials are paintable, tough, have low shrinkage characteristics and the two-part products come in 51 colors.

Quikrete Self Leveling Polyurethane Sealant

Sika Polyurethane Sealants

Sika Corporation, based in Lyndhurst, NJ, is a leading supplier to industrial markets including construction, transportation, marine, and automotive. Its efforts are focused on sealing, bonding, damping, reinforcing and protection. Sika’s product lines include concrete admixtures, specialty mortars, epoxies, structural strengthening systems, industrial flooring, sealants, adhesives, specialty acoustic and reinforcing materials.

Tremco Polyurethane Sealants

This page on Tremco’s site has links to their polyurethane, silicone and hybrid polyurethane sealants. (Tremco refers to their hybrids as being “silane end-capped urethane” rather than “silyl-terminated”, one of several terms used by others.)

Sealant Primers

Most, if not all sealants, can be applied to many substrates without preparing the substrate with a primer. There are however conditions where joints installed without primer fail adhesion tests and in those cases the joint installation or restoration process will include application of the correct sealant primer.

BASF MasterSeal P 173 and P 176 (formerly: Sonolastic Primer 733 and Primer 766)

Masterseal P 173 is a quick drying solvent-based primer for priming joints and substrates before application of MasterSeal NP 1™, TX 1, NP 2™, CR 195, SL 1™, SL 2™, and NP 150™ series sealants. MasterSeal P 176 is a high-solids, low-VOC solvent-based primer for priming joints and substrates before application of MasterSeal NP 1, TX 1, NP 2, NP 100™, CR 100 and CR 195 sealants.

Chem Link, NovaPrime Concrete Primer

To increase sealant adhesion where necessary such as in joints that expand or joints that include dissimilar or porous substrate materials. For use on concrete, masonry, granite, limestone and other materials.

Dow Corning® 1200 OS Primer Clear

1200 OS Primer is a one-part, VOC-compliant silane primer for use with Dow Corning® sealants.

Dow Corning® Primer C

one-part, film-forming primer for use with Dow Corning® sealants on painted and plastic surfaces to promote fast adhesion.

Dow Corning® Construction Primer P

Construction Primer P is a one-part, film-forming primer for us with Dow Corning® sealants on porous and cementitious surfaces to promote adhesion. It should not be used with Dow Corning® 790 Silicone Building Sealant, Dow Corning® Contractors Concrete Sealant or Dow Corning® parking structure sealants.

MasterSeal P 179 (formerly: Sonolastic Primer 2000)

porous surface primer for improved adhesion of MasterSeal NP 150, solvent-based, hybrid (silyl-terminated-polyether) sealant

Silicone Sealant

Silicone sealant is perhaps the most widely used material in the joints within and between building envelope components.

Dow Corning Products

Dow Corning’s “Construction Renovation” Products

Companies such as Dow Corning who make thousands of products have to organize everything from business units to web sites according to numerous criteria. Dow’s products and the information they provide on them are both excellent. In many industries they are the best. This link is to a page that lists eleven products used in building envelope joint restoration. Two of the sealants on the list are Dow 790 and Dow 795 sealants which are two of the most widely used in the business.

Dow Corning Weathersealing Solutions

This link is Dow’s portal to information on their products, including their many structural and non-structural silicone sealants.

Dow Corning Products for Architecture

Dow’s web site allows searching for products by Application, Industry, Product Group, Functional Group, Regulation and Properties / Characteristics. This link is to a page with links to sixty products in the “Architecture” Industry many of which are used in building restoration.

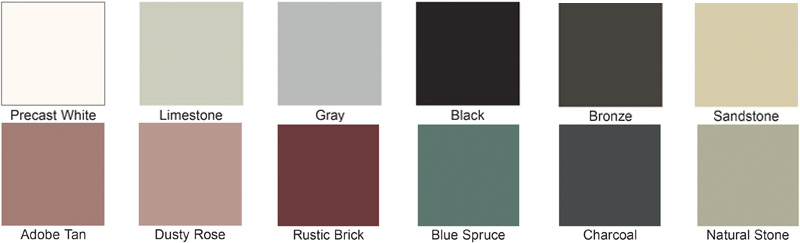

Dow 790 Standard Colors

Pecora Corporation

If Pecora products are not specified they are always an acceptable equal if not superior alternative.

Structural Silicone Sealant

Sealant is classified as “structural” if it is intended to carry loads. Silicone sealant has been used in that capacity since the 1960s. This Durability + Design article describes the application and offers a little history as well.

Tremco Commercial Sealants and Waterproofing

Tremco is an industry leader in many kinds of sealants used in construction. Their silicone products are among the best.