Manufactured Joints and Extrusions

Joints in buildings are usually closed with gunnable sealant but when joint width exceeds the standards factory made assemblies can be a reliable alternative and some waterproofing problems involving surfaces and edges that form irregular or out-of-plane spaces can be corrected with custom shapes.

When Are Gunnable Sealants the Wrong Choice?

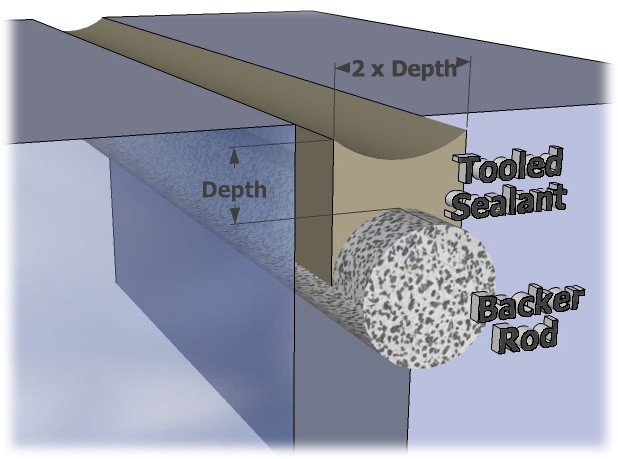

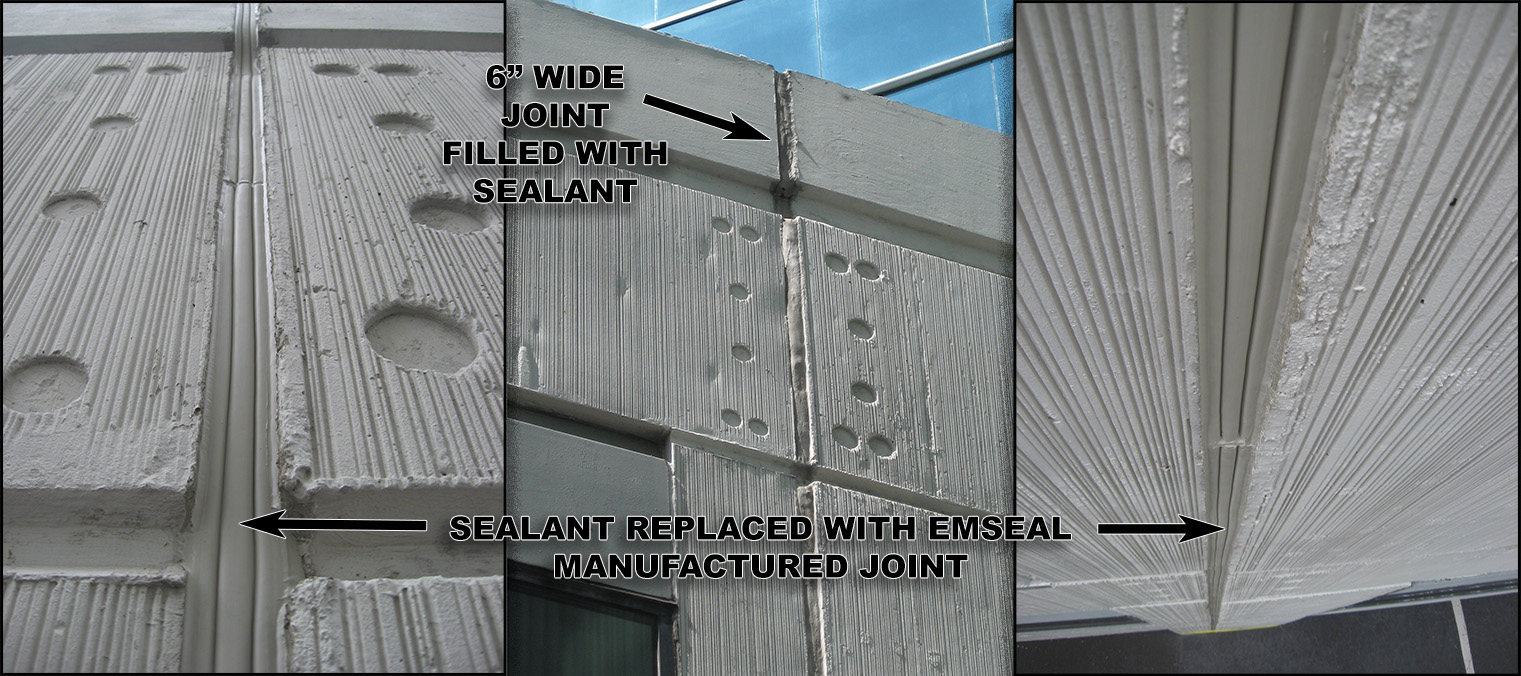

In a joint such as the one pictured below the optimal shape resembles an hour glass, and the width to depth ratio is 2:1. In such a joint the cured sealant can elongate and compress as needed to accommodate significant expansion. If the joint shape varies from that of an hourglass and the width exceeds twice the depth the stresses on the sealant as it stretches and compresses are greater and joint failure more likely. The Dow Corning Technical Manual allows for joint widths up to 4″. It also says that joint depth should not exceed 1/2″, regardless of the width. To stay within the guidelines the width to depth ratio of a 4″ wide joint would be 8:1, which is a difficult shape for the tradesman to create. The pictures of the joints above illustrate a common result. In the image on the left and the one in the center the joint is too thin and the stresses have caused the sealant to tear. This is called a “cohesive” failure. On the right the backer rod was placed too far down in the joint causing the sealant depth to be greater than the 1/2″ maximum. The stresses that occurred in this case caused a failure of adhesion. The sealant has separated from the substrate, which can be seen at the bottom of the image (just below the repair).

Manufactured joints could have been employed to correct for whatever happened during construction that caused these joints to be so wide. Although the changes would have justified an extra charge by the sealant contractor the expense would have been a fraction of the costs the owner eventually had to bear. This condition existed throughout the building envelope and was the cause of significant leaks, which didn’t occur until long after the sealant installer’s warranty had expired.

Emseal Products

Emseal Seismic Colorseal

Emseal Corporation is a manufacturer of engineered, factory made joints that can reliably seal the spaces between building components that are too wide for sealant.

Emseal Wall Joints, Above Grade Selection Guide

Colorseal & Seismic Colorseal Installation Guide

Emseal DSM System Installation Guide

Erie Metal Specialties, Akron, NY

Expansion joint systems and products

Polycholoroprene (neoprene) Preformed, Extruded Compression Seals

D.S. Brown Delastic® preformed compression seals

For highway and bridge applications as well as spillways, dams, parking structures, stadium ramps and pedestrian overpasses.

Silicone Extrusions

Some waterproofing problems involving substrate surfaces with insufficient sealant contact area or edges that form irregular or out-of-plane spaces shouldn’t be corrected with conventional wet seals. Leaking skylights or windows, leaks in a metal roof, leaks in RV’s or cargo trailers may involve such interfaces.

Adhesives and Sealants Industry Magazine Article on extrusions & preformed shapes

Information on pre-cured joint sealants that are produced by extruding material similar to wet sealant and allowing it to cure to an elastomeric product in a controlled manufacturing environment.

DOW 123 Silicone Extrusion

Dow Corning, Tremco and other silicone manufacturers make standard and custom silicone extrusions. Dow’s “123” product can be supplied as a tape or in a custom cross section that is adhered to EIFS or other building surfaces with silicone sealant.

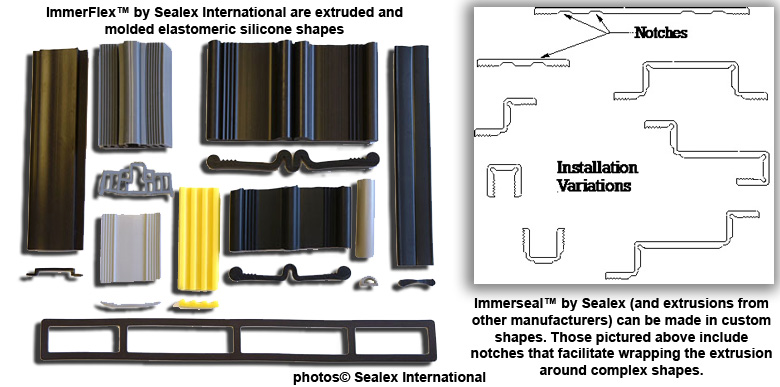

Sealex, Inc. Immerseal

Sealex, Inc. has developed a unique low viscosity extrusion process utilizing moisture-cure silicone chemistry to manufacture its ImmerSeal® line of pre-cured silicone sealant products. Complex extruded cross sections and molded forms are available.

Spectrum® Simple Seal Extruded Silicone Bridge

“Simple Seal” is an ultra-low modulus preformed silicone extrusion, or tape, with high elongation meant to be bonded to a wide range of substrates with Tremco Spectrem 1 or Spectrem 2 silicone sealant to form a waterproof seal. It’s meant for new construction or restoration work. Window perimeter and EIFS joints, parapet walls, skylights, aluminum window seals, transition seals, curtain wall joints, sheet metal roof joints and other lap joints are common applications.

Tremco Custom Silicone Gaskets when wet seals aren’t appropriate

3D, CAD graphics illustrate how custom silicone gaskets can work where wet seals won’t.

Other Tremco Products

Tremco Proglaze ETA – Engineered Transition Assembly

Proglaze ETA is a transition assembly for bridging the space between the window and/or curtain wall openings and the adjacent air and vapor barrier materials. “System 3” is comprised of a Silicone Rubber Extrusion (SRE) with a lock-in dart that will fit a majority of pressure bar race conditions. The Silicone Extrusion is available in 4” and 8” widths and is packaged in 50′ coils.

Proglaze ETA Installation Instructions

Air Barrier tie-ins and transitions by Tremco