Penetrating Sealers

There are many methods and materials for making building and infrastructure surfaces resistant to chemicals and the elements. They can be categorized according to the surfaces they’re meant to protect, what those surfaces need to be resistant to, the mechanism the material utilizes to fulfill its purpose or the material chemistry. For example, the coating often applied to marine structures and steel bridges is a three-coat system consisting of a zinc-rich primer, an epoxy midcoat and a polyurethane topcoat. That coating system would fall under the categories of marine paint and steel coatings. The system components are categorized as primers, intermediate coatings, topcoats, epoxies and polyurethanes. A product described as “a water-based, high-build, elastomeric, 100% acrylic waterproof coating for above-grade concrete, masonry, stucco and EIFS” can be categorized according to each of those terms and more. Penetrating sealers constitute a category of waterproofing material primarily because of how they work which is to penetrate the substrate to a depth of as little as an eight of an inch (3 mm) to as much as three-quarters of an inch (19 mm) and then effect the material they penetrate on a molecular level. Although the CATEGORIES are numerous, penetrating sealers are CLASSIFIED according to the chemicals they’re made of, which are:

- Silanes, which are:

Inorganic (does not contain carbon)

Very low viscosity, 4 angstroms (deep penetration)

Hydrophobic (repels water)

Oliophobic (repels oil)

Forms covalent bond with minerals (non-film forming)

Non Cross-Linking

Common Function – sealing dense surfaces such as high performance concrete, clay bricks, dense stone.

- Siloxane Blends, which are:

Organic (contains hydro-carbon)

High viscosity, 100 angstroms (shallow penetration)

Hydrophobic (repels water)

Oliophilic (bonds with oil, Hydrocarbon Bond)

Forms covalent bond with minerals (generally non-film forming)

Non Cross-Linking

Common Function – sealing very porous substrates such as block

- Water-Based Siloxane

- Silane / Siloxane Blends and Emulsions

- Alkylalkoxy Silane and Siloxane

- Hydrophobic Powders (concrete additive not topically applied)

- Siliconates, which are:

Organic (contains carbon)

Medium viscosity, 20 angstroms (moderate penetration)

Hydrophobic (repels water)

Oliophobic (repels oil)

Forms cross linked methyl-silicone resin (internal membrane)

Cross-Linking

Common Function – sealing porous concrete, brick and stone and curing new concrete

- Silicates

Inorganic (does not contain carbon)

Low viscosity, 8 angstroms (deep penetration)

Hydrophobic (reduces porosity)

Oliophobic (reduces porosity)

Forms calcium-silicate-hydrate (non-film forming)

Non Cross-Linking

Common Function – densifying machine trowel concrete, sealing and coloring vertical stone, masonry, concrete

- Penetrating Epoxies

Another important aspect of penetrating sealants that can establish a category is their vehicle, or “base” material. Many penetrating sealers are water based which makes them easy to handle and water will typically carry the solids that the sealer consists of into the substrate quite well. However, a hard limitation with water based sealers is surface temperature. Applying solids suspended in water to a freezing surface doesn’t work which means those products can’t be used in many areas during long periods each year. Solvent based penetrating sealers can be applied at lower temperatures, typically as low as 20 degrees F. Volatile Organic Compounds (VOCs) in solvents are a health concern and pollution problem so they are strictly regulated. Using solvent based sealers can require the use of respirators and other precautions. Also, they can be the source of objectionable and even sickening odors so their use isn’t allowed under many conditions. In response to VOC regulations manufacturers have begun to use bases that are neither water or solvent based. Those vehicle or base materials are proprietary and therefor almost always unnamed.

General Information

Top 10 Concrete Sealer Questions

What concrete surfaces should be sealed? What if the concrete surface isn’t sealed? What’s the price of concrete sealers? What will the sealed concrete surface look like? How is concrete sealer applied and can I apply myself? When do I apply concrete sealer? What will my concrete sealer repel? Will concrete sealer make my concrete slippery? How long will my concrete sealer last? Is concrete sealer environmentally friendly?

Wisconsin Dept. of Transportation Evaluation of Concrete Deck and Crack Sealers

Of the thirteen penetrating sealers studied in 2005 to determine their effectiveness in sealing concrete for road surfaces two products, Sonneborn Penetrating Sealer 40 and Hydrozo Silane 40 surpassed the rest having the best performance and greatest depth of penetration, which was 3.1 mm for Sonneborn Penetrating Sealer 40 and 3.8 mm for Hydrozo Silane 40. Of the ten sealants tested in the study two were deemed best, Sikadur 55 SLV and Dural 335.

Construction Chemical Solutions by Dow Corning

This publication includes a list of Dow Corning chemicals that are constituents of sealants, water repellents and concrete admixtures. The physical and chemical properties of Silicones are covered. Silicone material classifications and their functional features are listed and described too. A table of twenty-five Dow products is broken down into nine categories: Silanes, Water Based Siloxane, Silane/Siloxane Blends (diluted in solvent), Silane/Siloxane Emulsions (diluted in water), Siloxane Blends, Hydrophobic Powders (cementitious-based materials additive), Siliconates, Specialty Fluids and Silicone Resin Emulsion.

Penetrating Sealers For Concrete

General information on penetrating concrete sealers on ConcreteNetwork.com

Waterproofing with Silicon-Based Materials

Water-resistant, breathable coatings on porous surfaces are usually silicon-based. Siloxane, silane, and silicone rubber, are the most common varieties. They’re effective in part because of their ability to penetrate substrates without effecting porousness. These silicon-based materials share a number of characteristics, for example they don’t noticeably alter the appearance of most surfaces or the underlying material’s breathability. The distinctly different attributes of siloxane, silane, and silicone rubber affect how they are manufactured and used.

Concrete Sealers FAQ at ConcreteSealersUSA.com

Linseed Oil

Three Year Field and Laboratory Investigation to Evaluate The Effectiveness of Linseed Oil as a Concrete Sealer

This study published in 1989 determined that Linseed Oil was more effective than Silane or Siloxane penetrating sealers. “Test results indicated that the linseed oil sealer was the most effective sealer in reducing the intrusion of chloride ions into the concrete as well as reducing surface scaling and remained effective when subjected to salt water absorption after abrasion.”

Penetrating Epoxies

EpoxyProducts.com

Although poorly designed, this site includes a great deal of information and an extensive list of epoxy products.

The term ‘penetrating’ epoxy is vague, which is a feature of many of the terms used to describe not just penetrating sealers but other kinds of paints and coatings as well. This is because some suppliers and manufacturers don’t want to disclose what their products consist of. Usually a penetrating epoxy is an epoxy resin in a lot of solvent. The solvent(s) soaks or penetrates into the wood or other substrate carrying some of the epoxy with it. The degree of penetration can vary widely. If the substrate is resistant to the vehicle (solvent or water) it won’t soak very far into the surface. Also, penetration can be shallow if the substrate is damp or wet.

Prosoco

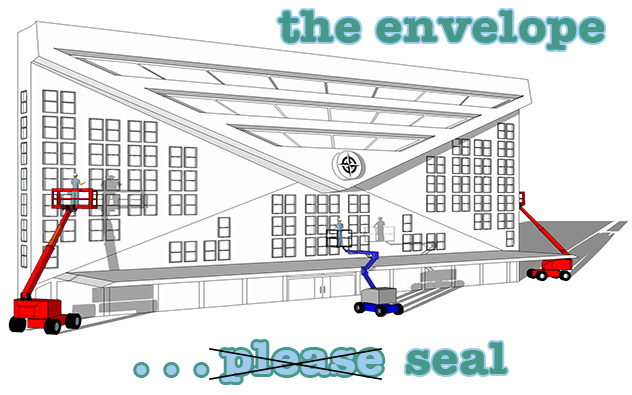

PROSOCO is a US company with very extensive experience and success as a manufacturer of products for cleaning, protecting and maintaining concrete, masonry and tile; making building envelopes air and water-tight; and cleaning, protecting and restoring new and existing masonry buildings.

Solvent Based Penetrating Sealers

BASF MasterProtect H 1000

MasterProtect H 1000 is a clear, breathable, high-performance, 100% silane, water repellent sealer that achieves highest depth of penetration. No masking of windows necessary and requires no cleaning after application No residue, will not harm glass windows, metal frames, or painted surfaces. Solvent based, excellent for cold weather applications. Superior water repellence so it penetrates deeply and chemically reacts within the pores of concrete to provide long-lasting protection Abrasion resistant so it provides long-lasting protection to horizontal substrates subject to traffic, such as bridge decks and highway surfaces.

JVS Building Services Page on BASF Masterprotect H 1000

This page includes sites where BASF MasterProtect H 1000 has been applied in Texas, the Mid-Atlantic, USA and in the Northeast of the United States. There is also a short video showing the result of applying the material to a vertical, pre-cast concrete surface in Norfolk, Virginia, USA.

Evonik Industries Protectosil® CHEM-TRETE® 40 VOC

Active Substance isobutyltrialkoxysilane, Active Content >50% by weight, Solvent denatured ethyl alcohol

Non-water and Solvent Free Based Penetrating Sealers

New VOC Regulations Effective January 1, 2009

Explanation From Evonik Degussa about VOCs and overcoming the conflicts between being able to use waterproofing materials that can be applied at low temperatures and meeting VOC regulatory requirements.

Evonik Degussa Protectosil CHEM-TRETE BSM 400

Twenty year service life, solvent free non-water based, 100% pure silane, 20 degree F application temperature, for masonry, particularly brick, and concrete.

Water Based Penetrating Sealers

Cathedral Stone Products masonRE R97

The technical data on this product reads as similar literature from other manufacturers. However, Cathedral Stone Products is an outstanding company that distinguishes itself from others through its services and reputation. Any product they put on the market is probably good.

BASF MasterProtect H 400 Alkylalkoxysilane

Water Based, 40% Silane, Formerly Enviroseal 40

Prosoco Products Sure Klean Weather Seal Siloxane PD

Sure Klean® Weather Seal Siloxane PD (predilute) is a ready-to-use, water-based silane/siloxane water repellent for concrete and most masonry and stucco surfaces.

Silane / Siloxane

BASF MasterProtect H 177

Formerly Enviroseal Double 7 for Brick, H 177 is a high-performance, water-based, VOC-compliant, clear silane/siloxane sealer designed for dense, vertical masonry surfaces like hard-burnt brick.

Dow Corning IE-6694 Water Repellent Emulsion

This low VOC product comes is a 60% active silicone water repellent that can be added to paints and other coatings or diluted with water to low concentrations and applied to porous substrates such as concrete and block.

Silicates

ConcreteSealersUSA

Lithium Silicate and Sodium Silcate penetrating sealers are breathable sealers that react with cementitious material to increase its density, hardness and strength, reduce water absorption tendency, reduce dusting and efflorescence and decrease maintenance requirements. The effect on the cementitious material is what distinguishes this category of sealers from others and it can effect the texture making a floor more slip resistant or a wall more polished if the sealer is applied with a scrubber or polisher.

Cathedral Stone Potassium Silicate Products

Conproco M3P

Spray, roller or brush applied mineral silicate stain / paint with siloxane component.

KEIM Concrete Systems

Mineral Silicate products from the company founded by the inventor of the fresco preparation and creation process, Adolf Keim, in 1884. Colored mineral silicate paints by KEIM can transform dull and plain concrete and masonry surfaces and stucco. Potassium silicate paints penetrate and permanently combine chemically to the substrate to which they are applied never to blister or peel. The process is called “petrification” and it produces a surface that is vapor permeable, non-combustible, reflective and resistant to fungus, algae and mold.